System Operation Description:

Note: This engine is equipped with a permanent timing calibration sensor due to the lack of accessibility to the timing calibration hole in the flywheel housing. The timing calibration sensor is used to calibrate the engine speed/timing signal against top center on the flywheel.

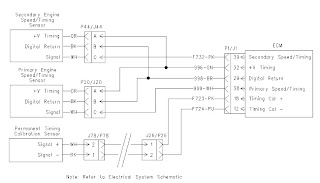

Ilustration Schematic

If any of the following conditions have occurred, the speed/timing sensors should be calibrated:

* Replacement of the ECM

* Servicing of the engine timing gears

* Replacement of either of the speed/timing sensors

* Active 261-13 Engine Timing Calibration required

There are two speed/timing sensors that provide information about the speed of the engine and information about the position of the crankshaft to the ECM. Each sensor generates a pulse signal as the timing ring rotates past the pickups of the sensors (slipheads). A secondary speed/timing sensor allows the engine to continue to operate if there is a failure of the primary speed/timing sensor. If both speed/timing sensors would fail, the ECM would discontinue power to the unit injectors.

The ECM provides the engine speed/timing sensor with 12.5 ± 1.0 VDC. A unique tooth on the timing reference gear generates a unique duty cycle. The signal provides the ECM with information on the engine position.

Test Step 1. Check for Active Diagnostic Codes

1. Connect ET to the service tool connector.

2. Check for any active diagnostic codes.

Expected Result:

No active diagnostic codes are present.

Results:

* OK - No active diagnostic codes are present.STOP

* Not OK - 261-13 (Engine Timing Calibration required) is the only active diagnostic code that is present. Proceed to Test Step 2.

* Not OK - There are active diagnostic codes. 261-13 (Engine Timing Calibration required) is not one of the active diagnostic codes.

Repair: Repair the active diagnostic codes.

STOP

* Not OK - A 261-13 (Engine Timing Calibration required) and other active diagnostic codes are present.

Repair: Repair the active diagnostic codes. 261-13 Engine Timing Calibration required may remain active.

Repeat Test Step 1.

Test Step 2. Calibration Procedure

1. Start the engine. Allow the engine to warm up enough to exit cold mode operation.

2. Select "Service" from the main menu on ET. Select "Calibrations" from the drop down menu. Select Timing Calibration.

3. Press the "Continue" button on ET. Wait until ET indicates that the ECM has calculated the timing reference.

Note: Engine speed will be set automatically by the ECM during the calibration.

Note: If ET displays "Calibration Unsuccessful", the electronic injection timing has not been calibrated.

Expected Result:

The timing should calibrate.

Results:

* OK - The timing calibration was successful.STOP

* Not OK - The timing did not calibrate. Proceed to Test Step 3.

Test Step 3. Static Timing of the Gear Train

Excessive backlash in the engine gear train will cause inconsistent timing. Refer to Disassembly and Assembly, "Camshaft - Remove and Install" for identifying and repairing a gear train problem.

Expected Result:

The gear train is timed correctly.

Results:

* OK - Repeat Test Step 1.